About TPU film

TPU, short for thermoplastic polyurethane elastomer (Thermoplastic polyurethanes), is also known as PU thermoplastic. It is a linear block copolymer consisting of oligomer polyol soft chain segments and diisocyanate-chain extender hard chain segments.TPU film is a film made on the basis of TPU granule material by special processes such as calendering, casting, film blowing, coating, etc. TPU film is an important application form of TPU material.

TPU film produced by extrusion casting with TPU granule material is characterized by high moisture permeability, air permeability, cold resistance, heat resistance, abrasion resistance, high tension, high tensile strength, high load support. Thus, its application can be extended to the field of plastics. Especially in recent decades, TPU has become one of the fastest growing polymer materials.

The composition of TPU is free of cadmium, lead, mercury, arsenic, chromium and barium by SGS ASTM F963, which is in line with the environmental protection standard. With the alternating development of industry technology, the use of TPU film to replace non-environmentally friendly film has become the trend of the world to promote environmental protection policies.

The use of TPU production of hot melt adhesive in the new products - hot melt adhesive film, also gradually began to start, development, and the current dominant position of the EVA hot melt adhesive and synthetic rubber hot melt adhesive compared to the hot melt adhesive, TPU hot melt adhesive film not only to meet the customer's demand for high viscosity, but also has the good physical properties of the TPU, such as good elasticity, mechanical TPU hot melt adhesive film will be one of the important development directions for the combination of plastic film and hot melt adhesive in the future.

TPU film is a sustainable modification of the new industrial materials, through the modification of raw materials, material formula adjustment, production process optimization, etc., to further optimize the performance, expanding the field of application, can be given a strong, sustained vitality. In addition to the plastics field other fields are also widely used.

TPU film processing technology

At present, the main processing methods of TPU film include blown film method, casting method, coating method, calendering method. Among them, blown film and casting method is the most common TPU film processing.

Blown film method

Because the film has a high degree of extensibility and elasticity, so in the blown film processing is relatively complex, it is difficult to carry out separate molding process, so the common process is easy to form PE as a backing co-extrusion molding process, that is, through the different extruders were TPU raw materials and PE raw materials plasticizing, extrusion processing, and in the co-extrusion die in the composite molding, the use of the PE layer will be peeled off and then recycled.

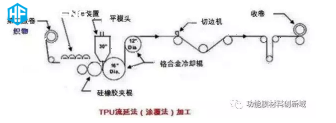

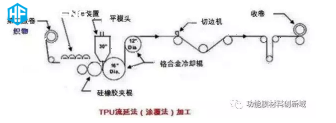

【Flow Extrusion Coating Method

TPU extrusion coating is a production process of laminating molten TPU on the substrate, TPU resin is extruded and melted in the barrel of the extruder, and then extruded between two rollers through a flat die head with downward pressure, and at the same time, the substrate is hauled into the molten plasticized material and rubber pressurized rollers. The pressure of the pressurized rollers is controlled to fit the plasticized TPU material to the substrate, and the hot tape is cooled by the metal rollers, trimmed, rolled, and molded into application products in one process.

Processing Characteristics of TPU Film

TPU resin has strong hygroscopicity, and its granular material will cause processing problems and reduce the quality of the finished product if it contains too much moisture. Therefore, the TPU material and processing aids must be dried before processing. The moisture content of the dried granular material should not exceed 0.02% by weight. The dried resin should be stored immediately in dry containers that can be securely sealed to avoid reabsorption of moisture. In general, if the plasticized TPU film has a foaming site or bubbles appear, it means that the drying effect is not good.

Due to the high density and elasticity of the TPU pellet resin, and the high temperature characteristics after drying, the resin is prone to bridging in the ordinary hopper and not feeding, so it is necessary to make a special design for the hopper and the barrel of the dropout. Considering the high price of TPU resin, the weighing feeding system can effectively save the consumption of raw materials.

Points to note for TPU processing

TPU melt is very sensitive to shear and temperature, too high shear will lead to product performance degradation, too high temperature will lead to melt decomposition, so the extruder and screw design has certain requirements. Generally by reducing the screw speed to control the processing temperature and shear rate in the extrusion process, but this will lead to a decline in the extrusion volume, so it is recommended to use a barrier-type forced feed screw with a smooth barrel to solve the problem of extrusion volume.

TPU film has good tensile elasticity, so in the haul-off and winding process must be careful, generally in the haul-off process to maintain the stability of the tension and reduce the traction force as much as possible, so some of the equipment used in the way of closed-loop control of tension to achieve constant tension traction, to ensure that the stability of the tension, and winding through the gap winding way to wind.

Ten characteristics of TPU film

Top Ten Properties of TPU Film

来源:功能膜材料创新域综合整理

Top Ten Properties of TPU Film

Top Ten Properties of TPU Film