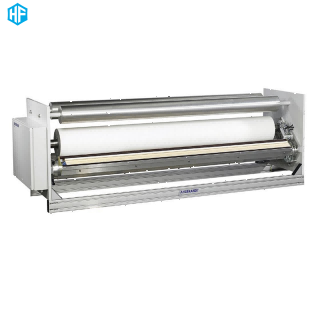

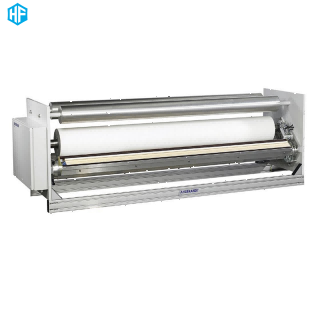

Corona treatment is a very important film treatment process in film processing. Generally speaking, it is an electrostatic treatment on the surface of plastic film by high frequency voltage, so that the surface of the film has higher adhesion, which is convenient for the post-processing of the film, such as printing, coating, composite materials, and so on. Hopfen Machinery Group The following are the three main parameters of corona treatment.

1. Corona treatment voltage

The voltage applied on the treatment device rises, the treatment effect is enhanced, but the effect has no linear relationship. Therefore, when the treatment voltage rises to a certain value, the treatment effect will not be obvious.

Since the corona treatment voltage and film thickness is positively correlated, the higher the film product, the higher the treatment voltage. Typical treatment voltages used for thin films range from 10,000-20,000V. The AC power supply fed to the corona processor must be stable, otherwise the output high frequency voltage will fluctuate, resulting in time-dependent differences in film treatment results. For manufacturers with fluctuating power supplies, an AC voltage regulator should be used to ensure voltage stabilization.

2. Output power of the corona processor

Due to the corona treatment speed, film type, experience, width, etc., the applied treatment power is different. Currently commonly used corona treatment of the output power range of 2-70kW, if the processing speed increased by a factor of 1, the processing power should also be increased by a factor of 1; similarly, if the film width increased by a factor of 1, the processing power should also be increased by a factor of 1; the power of the cold film processing at least 1 times as much as the hot film. The above can also be used as a basis for purchasing corona processor sizes.

The treatment device can be thought of as a capacitor with a lossy dielectric. As the input power frequency increases, the current increases and the power increases, and vice versa. Corona processors typically change the amount of power by adjusting the frequency of the power supply. Corona processor frequency adjustment range: 10-25kHz.

3. Corona processor electrode gap

Electrode gap is the spatial distance between two electrodes, i.e., the spatial distance from the discharge head to the edge of the ground electrode. It has two effects on the degree of treatment, on the one hand, the gap increases, the corona treatment range is wider, the relative residence time of the corona treatment film is longer, which is conducive to improving the treatment effect; but on the other hand, the energy is dispersed to a larger space, the intensity of the treatment is reduced, and the treatment effect is poorer; only in the appropriate electrode gap, the intensity of the treatment is maximum.

Electrode gap is usually controlled at 1-2mm which is suitable. In addition, changing the single-head electrode to a multi-head (e.g., 6-head) electrode can also improve the degree of treatment under the same processing conditions.

Due to the different film types, post-treatment forms, and post-treatment times, the following table provides several critical surface tension values required for film printing and composites. If the post-treatment is carried out immediately, the minimum value is taken into account, otherwise the maximum value should be referred to.

Hefeng Machinery Group focuses on the development and application of surface treatment industry for more than 20 years, corona machine, corona treatment machine, plasma machine, static generator, static eliminator, dust removal machine, UV curing, UV power supply, electronic UV, UV light box, plasma treatment system, vacuum plasma, spark machine, plasma treatment, flame treatment machine, electronic spark machine, EDM impingement machine, surface treatment machine, polymer Surface Flowering Machine, UV lamp, UV transformer, and so on. It is a national high-tech enterprise integrating R&D, production and sales.

Our core competitiveness comes from the fact that we never stop launching new products and designing molds, and vigorously investing in the research and development of new products, it is this guiding principle that makes us different, which also enables us to become a real solution-oriented company in the industry. From the design of the solution to the final inspection of the equipment, we pay meticulous attention to every detail to ensure that the quality of our products and customer service meets the highest standards, and with our highly qualified service team and experienced technicians, we have gained an international reputation as a solid and reliable partner.

If you want to know more, you can contact online customer service!